Choosing the Right Air Tool for Your Projects

Key Takeaways

- Identify the specific job requirements to select the appropriate air tool.

- Consider the power source, size, and weight of the tools you need.

- Learn about common air tools and their distinct applications.

Selecting the right air tool is crucial for the success of any project, whether you're a DIY enthusiast or a professional contractor. With various types of air tools available, it can be overwhelming to decide which one will best suit your needs. In this guide, we'll cover essential air tools, their specific applications, and tips on how to choose the best options for your projects. Let's dive in!

Understanding Air Tools

Air tools, also known as pneumatic tools, rely on compressed air to operate. They are lightweight, powerful, and often preferred in various industries, including automotive, construction, and woodworking. Some prominent examples include impact wrenches, nail guns, air hammers, and spray guns.

Types of Air Tools

| Tool Type | Description | Common Uses |

|---|---|---|

| Impact Wrench | Delivers high torque output with minimal effort | Automotive repairs, heavy equipment maintenance |

| Nail Gun | Fires nails using compressed air | Construction, framing, and cabinetry |

| Air Hammer | A tool that uses quick bursts of air to drive nails or break materials | Demolition, removing rust, and cutting sheet metal |

| Spray Gun | Used for spraying paints or coatings | Paint application, automotive refinishing |

How to Choose the Right Air Tool

When selecting an air tool, consider the following factors:

- Project Requirements: Understand the specific tasks you'll be performing.

- Power Source: Choose between electric or pneumatic tools based on your needs.

- Ergonomics: Opt for lightweight tools to reduce fatigue during extended use.

- Specifications: Check the power output and capabilities of each tool.

Featured Air Tools

AIRCAT Pneumatic Tools 1150 1/2-Inch Composite Impact Wrench

This durable power impact wrench provides 900 ft-lb maximum torque and is designed for automotive repairs and maintenance with low noise levels.

Learn MoreCommon Applications for Air Tools

Air tools excel in various applications, including:

- Automotive repairs – Impact wrenches and air hammers are commonly used.

- Construction – Nail guns and spray guns are favored by contractors.

- Woodworking – Pneumatic sanders and routers enhance precision and efficiency.

Pros and Cons of Air Tools

Pros

- Lightweight and easy to handle

- Powerful performance for heavy-duty tasks

- Quieter operation compared to electric tools

Cons

- Requires a compressor for operation

- Potentially higher initial costs

- Hose management can be cumbersome

Conclusion

Choosing the right air tool can significantly enhance your project's efficiency and effectiveness. By understanding the different types of air tools and their applications, you will be better prepared to make informed decisions. The options available cater to various tasks, making it essential to assess your specific needs before selecting a tool.

Further Reading

For more insights on power tools, you might find the following resources helpful:

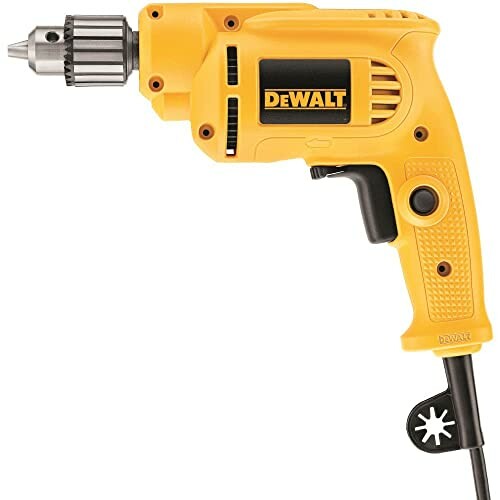

DEWALT Corded Drill with Keyed Chuck, 7.0-Amp

Offers versatility and power with a compact design, making it ideal for a variety of tasks in tight spaces.

Learn MoreAir Hose Reel 100 Ft Retractable

Features an automatic rewind system ensuring tangle-free operation and ease of use across multiple projects.

Learn More